The entire production process is integrated into a specialised computerised monitoring and control system, which allows live monitoring of the technical and qualitative production parameters and indicators, both on-site and remotely 24/7.

From special hoppers, the materials (batch) required for glass melting are loaded onto conveyors at a given weight ratio, mixed with glass cullet and fed into the melting furnace.

The melting furnace is a complex structure made of refractory materials for melting glass. It reaches a temperature of 1600°C.

From the melting end, the melt passes on to the working end (distributor), then to the forehearth, which consists of a channel lined with refractory materials with a heating system, and then to the feeder mechanism. From here, the cut glass gobs are directed through special funnels to the forming machine.

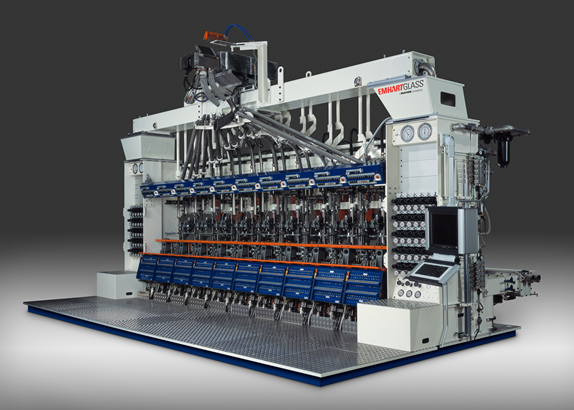

The bottles are formed by two Emhart Glass sectional double gob and triple gob computerised forming machines type IS-6 (6 sections of 2 gobs (DG) of glass each) and type AIS-8 (8 sections 2 or 3 gobs (DG or TG) of glass each).

The formed bottles go to the Certincoat “hot end coating hood, where they are sprayed with a special coating that gives the bottle extra strength.

The bottles are then annealed and sprayed with another coating, slippery (“cold end coating”), to help them “travel” through the conveyors and avoid scratching the surface of the bottles.

Once sorted, the quality-checked bottles are conveyed via special conveyors to the packing department. It is equipped with a stacker that separates the bottles into rows, and a hoist (palletizer) that lifts the bottles onto cardboard or plastic overlays. This automated process puts the bottles in packs on wooden pallets.

The bottles are then transported to a shrinking machine and encased in a sleeve of heat-shrink polyethylene film. When hot air is blown down the frame, it warms the thermal film, which shrinks as it cools and wraps the bottles tightly around the package.

This way, the bottles are clean, protected from dust and rain, and arrive safely at the end of their journey to the consumers – the companies that produce the beverages.

Glass is 100% recyclable and can be recycled an infinite number of times without any negative impact on the quality of glass or its contamination.

The batch used to melt the glass contains as much as 70-75% of the cullet that is remelted.

Glass packaging preserves food or drinks for a long time without any contamination. A large proportion of the bottles produced are used as recyclable bottles, i.e. for more than one refill, thus making a significant contribution to saving the environment.